Do you want to make dry ice blocks? Do you know the detailed production process of making dry ice cubes? Do you want to know the common sizes, weights, and prices of dry ice blocks? Do you want to know the uses of dry ice cubes? Then you can read this article where you can find all the answers to these questions. This article details the production process of dry ice blocks, the processing specifications, and the uses of dry ice cubes. If there is anything else you would like to know more about dry ice, please feel free to ask us for answers.

What are dry ice blocks?

Dry ice block is a specialized freezing medium made from solid carbon dioxide (CO2). Typically, liquid CO2 is placed in a high-pressure container and the temperature and pressure are lowered through a pressure-reducing valve, causing it to rapidly transform into a solid state, known as dry ice blocks or dry ice pellets.

Properties of dry ice blocks

- Extremely Low Temperature: Dry ice blocks have a very low temperature of about -78.5 degrees Celsius (-109.3 degrees Fahrenheit). This makes it a very effective coolant.

- Rapid Evaporation: Dry ice cubes evaporate quickly at room temperature and convert to carbon dioxide gas. This rapid evaporation makes it useful for special effects, staging, and cleaning applications.

- Leaves No Residue: Dry ice bock leaves no moisture or residue behind when it evaporates, making it ideal for applications such as food transportation and laboratory experiments.

- Heavy: Dry ice block is heavier than water, which makes it more stable during refrigerated packaging, transportation, and storage.

- Conductive: Since dry ice cubes are electrical insulators, they are safe to use in some electronic devices that require cooling.

- Safety Precautions: Proper ventilation is required when using dry ice blocks because carbon dioxide gas from its evaporation can build up in confined spaces. Direct contact with dry ice cubes can result in frostbite, so protective measures need to be used.

How to make dry ice blocks in mass?

Processing dry ice blocks requires the use of specialized equipment, which usually includes a dry ice block press machine. Below are the general dry ice processing steps:

- Liquid CO2 Supply: First, liquid carbon dioxide (Liquid CO2) needs to be prepared. This is usually accomplished by connecting a line or cylinder to a liquid CO2 supply source.

- Compression of Liquid CO2: The Liquid CO2 is compressed and piped to the ice cube machine.

- Refrigeration System: The dry ice cube machine contains a refrigeration system that converts the liquid carbon dioxide into a solid state. In the machine, the pressure of the liquid carbon dioxide is rapidly reduced, causing some of the liquid carbon dioxide to be converted to gaseous and solid states.

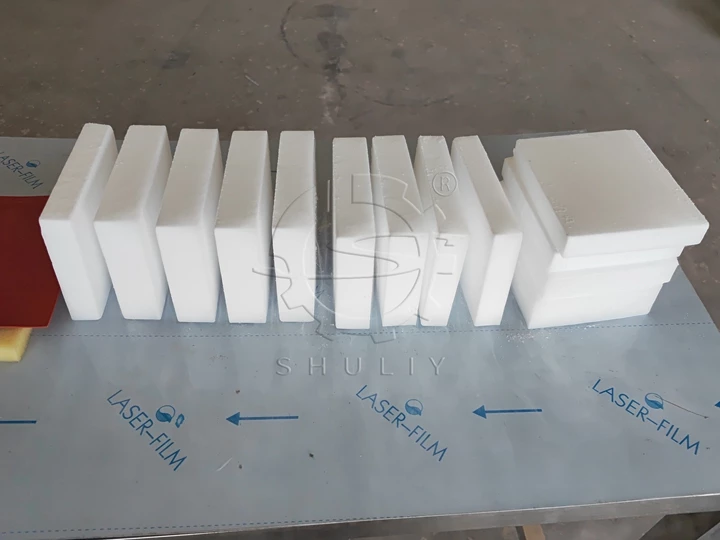

- Squeezing and Cutting: The manufactured dry ice blocks are formed into blocks of the desired size by means of a squeezing mechanism and a cutting mechanism. This usually involves squeezing the dry ice cubes through a die or blade to form uniform blocks.

- Collection and Packaging: The molded dry ice cubes are collected and sent to the packaging area. Typically, the dry ice cubes are packaged into suitable containers to prevent them from evaporating prematurely.

- Storage and Distribution: Processed dry ice blocks may be stored in appropriate dry ice holding tanks or warehouses and then distributed to customers via cold chain transportation.

Common dry ice block sizes, weights, and prices

Dry ice block sizes, weights, and prices can vary by supplier, region, and market demand. Here are some common dry ice block sizes for reference:

Dry ice block sizes: Common sizes of dry ice blocks include square blocks and rectangular shapes. Square blocks usually measure between 2 inches (5 cm) and 3 inches (7.6 cm), while rectangular blocks can be larger.

Dry ice block weight: The weight of dry ice blocks can vary depending on the producer and customer needs. Common weight ranges include anything from 1 pound (0.45 kg) to 50 pounds (22.7 kg). Lighter-weight blocks are suitable for small refrigerated packages, while larger blocks are used for larger-scale applications such as cold chain transportation.

Dry ice block price: Dry ice is usually priced by the pound, and the price can be affected by a number of factors, including geographic location, market demand, availability, and how the dry ice is produced. In general, dry ice is relatively expensive because its production and transportation processes require specialized equipment and conditions.

To obtain accurate dry ice block price and specification information, it is recommended to contact your local dry ice supplier or manufacturer directly. This is because prices and specifications may vary by region and supplier. In addition, some suppliers may offer customized dry ice block sizes and weights to meet specific customer needs.

Main uses of dry ice blocks

- Cold chain transportation: Dry ice block is a key element in cold chain transportation. It is used to keep temperature-sensitive items such as food, pharmaceuticals, and biological samples cold during transportation.

- Pharmaceutical preservation: Dry ice block is used in the pharmaceutical and medical fields to preserve and transport biological products, vaccines, blood, and medical samples.

- Food refrigeration: Dry ice blocks are widely used in the food industry, especially in the transportation and presentation of food products that need to be kept cold, frozen food, and seafood.

- Laboratory and scientific research: Dry ice block is used in laboratories for refrigeration, freezing of samples and experiments, as well as for special applications in some chemical experiments.

- Stage Effects: Dry ice is used in stage and special effects production to create unique smoke and fog effects.

- Cleaning and surface preparation: Dry ice cubes are used to clean and treat surfaces through dry ice blasting and cleaning techniques, especially in cleaning equipment and removing dirt.

- Food production and displays: Dry ice is often used to create special effects on food displays such as ice cream trucks and cold drink stands.