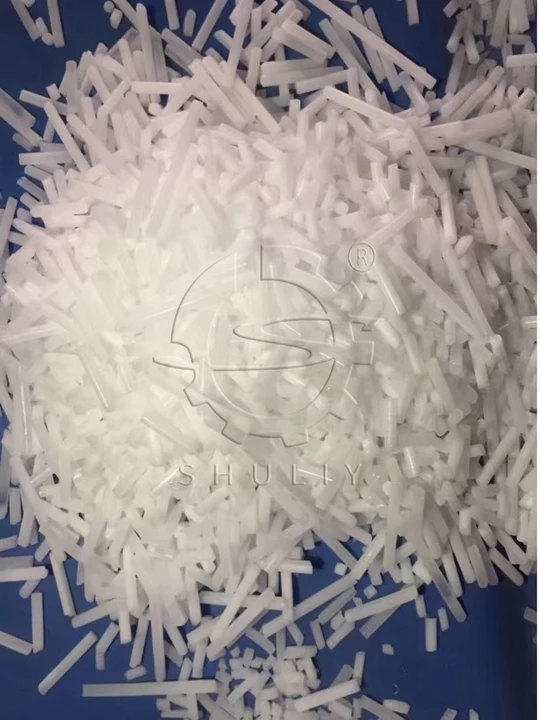

Dry ice pellets with a diameter of 3mm are widely used and are often used in dry ice cleaning and stage landscaping. Processing this kind of dry ice pellets requires the use of a special dry ice pellet making machine. Recently, many Indian users have asked our factory about processing methods of 3mm dry ice pellets. In this article, we explain in detail how to produce commercial 3mm dry ice pellets in India.

Why make 3mm dry ice pellets in India?

3mm dry ice pellets are used in many fields in India. Its low temperature and environmentally friendly characteristics make it an indispensable resource in many industries.

These small dry ice pellets are commonly used in the medical and pharmaceutical fields, especially in cold chain transportation.

They can be used to freeze and maintain vaccines, pharmaceuticals, and biologics at low temperatures, ensuring their quality and efficacy.

In addition, 3mm dry ice pellets play a key role in automotive and mechanical engineering. They are used to clean and remove grease, paint, and dirt from parts.

In film production and stage shows, 3mm dry ice pellets are used to create smoke and special effects to create a dramatic atmosphere. This is also the most frequently inquired use by our Indian users who want to process dry ice pellets.

Steps to Make 3mm Dry Ice Pellets in India

The process of processing 3mm dry ice pellets mainly includes: 1. Preparing liquid carbon dioxide raw materials; 2. Using dry ice pellet machines to process dry ice pellets; 3. Low-temperature storage and transportation of dry ice pellets.

Steps to Make 3mm Dry Ice Pellets

Prepare raw materials

Begin with high-quality liquid carbon dioxide (CO2). This is the fundamental ingredient for producing dry ice pellets. Ensure a reliable supply chain for uninterrupted production.

Buy dry ice pelletizer

Investing in a dry ice pelletizer is key. Shuliy’s Dry Ice Pelletizer series, renowned for its efficiency and precision, offers models suitable for commercial production of 3mm dry ice pellets. The machine’s advanced technology ensures uniform size and density, meeting industrial standards.

Pelletizing Process

The pelletizing process involves feeding liquid CO2 into the dry ice pelletizer, where it undergoes controlled expansion. This expansion forms tiny droplets that solidify into 3mm dry ice pellets. The speed and pressure are regulated to achieve the desired dry ice pellet size.

Collection and storage of dry ice pellets

Once the dry ice pellets are formed, they are collected and stored in insulated containers to maintain their temperature and prevent sublimation. Shuliy’s dry ie storage solutions offer reliability for businesses requiring efficient storage of their dry ice pellets.

Supply:

- Dry ice pellets

Tools:

- Liquid carbon dioxide storage tank, dry ice pelletizer, dry ice pellet storage box

Materials: Liquid carbon dioxide

Conclusion of Dry Ice Pellets Production in India

Producing 3mm dry ice pellets in India demands a strategic approach and the right equipment. Every user must carefully check their production conditions, raw material supply, budget, and finished product usage before investing in a dry ice pellet processing business.

Shuliy’s Dry Ice Pelletizer stands out as a reliable choice for businesses aiming to meet the growing demand for precision-sized dry ice pellets. Elevate your production capabilities with Shuliy’s expertise and advanced technology.

Contact for Shuliy’s dry ice pellet maker machine now

In a market where precision matters, Shuliy empowers businesses to create top-tier 3mm dry ice pellets efficiently and reliably. Contact us today to explore the possibilities for your business.