内容

1. 总体介绍

2.液压系统

3.电气控制系统

4. 安装与调试

5. 操作

6. 维护

7.故障排除

总体介绍

干冰造粒机是一种干冰机,可将液态二氧化碳制成干冰颗粒。

- 外形尺寸L1450*W800*H1250mm,净重580kg

- 生产能力

干冰尺寸:直径3mm和16mm;

干冰密度:食品级≥1.50

干冰容量:50公斤/小时

- Co2和冰转化率≥40%

- 液态Co2含水量<50ppm;液态Co2输入压力≤2.0MPa。

警告:液体充注或压力发生变化时禁止启动制冰机 二氧化碳 储存罐。

5、CO2气体通过带法兰的管道排出,必要时便于回收;排气口必须保持畅通。

6、总功率3.7kw。

液压系统

一、技术规格

A、最大系统压力为21MPa;

2、正常工作压力小于18MPa;

3、泵流量为31L/min;

4、电机功率:3.7KW;

5、油箱140升;

6、油箱尺寸为80*45*40mm

2、国标46#、56#、68#新型抗磨液压油(液压油运动粘度应在17-23 cSt之间,油液污染度应低于NAS标准12级);通过加油孔加油至油位计上限(约需350L液压油)。每6个月清洁一次,每12个月更换一次油。

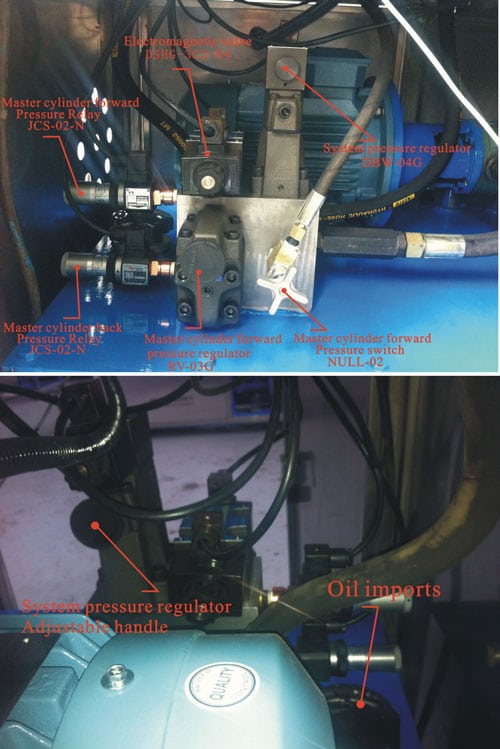

3、系统压力测试

电机按Δ接线方法接线,并保证顺时针方向正确。启动油泵,调节溢流阀控制系统压力。系统压力值将显示在左侧压力表上。而该系统压力为21MPa。建议:在满足机器功率要求的情况下,最好选择较小的压力。这样可以降低功耗;机器出厂前我们已经将系统压力调好在18-21Mpa之间。

4、压力继电器测试

压力继电器在出厂前已经过测试和调整。正常工作时,若启动过早或无任何动作,可通过压力继电器末端的按钮手动调节压力继电器;顺时针方向增加压力,逆时针方向减少压力。

5、注意事项:

A、油位偏低,吸油滤清器容易吸入空气,系统会振动,解决方法是:向油箱加油,让油位超过液位计,空转油箱数次,将油箱内的空气排出。

B、每6个月清洁一次吸油过滤器。

C、电磁换向阀和电磁溢流阀的电压为220V,因此要保证电压不低于220V。

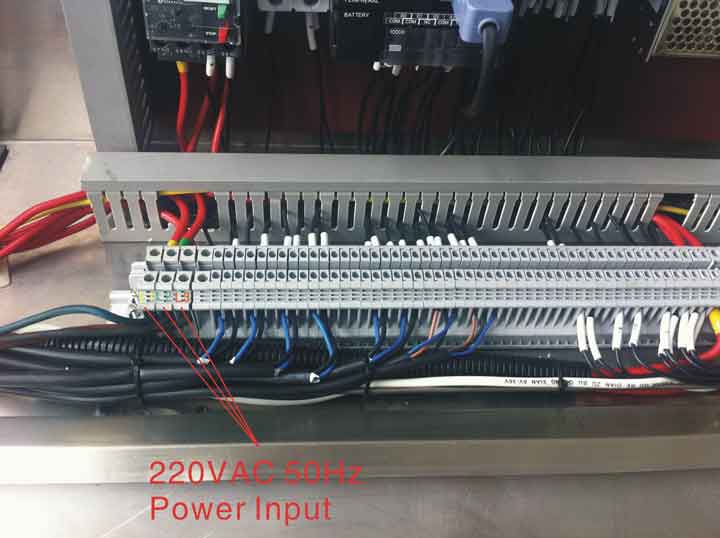

电气控制系统

进线为三相四线,尺寸为2.52毫米;将220VAC、三相50Hz的电源进线和零线接入机器右上方进线盒,并按电气规定拧紧。

警告:机器必须安全接地!

安装和调试

1安装

地面必须平整光滑,并固定好机脚。输送管及阀门管径不小于φ10,压力1.6~2.0MPa,液管必须保温。

警告:干冰制造车间应通风良好!

2启动制冰机

(1)打开电箱,按下并联断路器;

(2)接通进线箱主电源;

(3)松开船上“停止”按钮;

(4)在触摸屏上启动油泵电机;

(5)所有步骤均在触摸屏上操作。

注意:A.首次启动时请观察电机是否顺时针运行。

B.启动油泵后,可手动调节液压系统压力及换挡压力;出厂时系统压力为21MPa。

严禁油泵反转

(6)根据加工要求设定加料时间和保压时间;

(7)选择手动或自动运行方式;

(8)下班后关闭所有电源。

操作

1、首先手动打开外部液管阀门,让液态Co2进入机器。

2、然后启动电源、油泵、搅拌电机;按主缸进退,进给10秒,再按主缸进退,进给10秒,重复此动作数次。

注意:进料动作只有在主油缸处于后部时才开始;

只有当主油缸回位时才开始自动化动作。

3、压缩箱完全冷却后,会自动制取干冰。

注意:每次启动机器时,管道内会有大量CO2气体,用户必须用CO2气体吹扫压缩箱和除湿。

4、干冰调节

A、通过调节添加Co2时间参数来调节干冰产量:YGBK-50-1的调节参数为0.4-0.5KG。如果小于0.45kg,会影响出冰量,如果大于0.5kg,会影响CO2气体排放,对机器不利。

B、调整干冰大小

干冰的长度可以通过调节搅拌电机的转速来调节。

不同的模具可以生产Φ3-Φ16不同尺寸的干冰颗粒。

警告:

A.手动进料时,活塞必须推到底部。

B.进料电磁阀无法关闭时,立即关闭进料球阀(用户提供)。C.每次出冰量不得超过0.5kg。

C.油泵运行时,严禁将手靠近压缩箱的关闭门。

D.CO2无毒,但高密度CO2会使人窒息;因此,保持干冰厂通风良好至关重要。

E.CO2的固体形式——干冰,温度为-78℃,容易冻伤皮肤,因此接触干冰时必须采取适当的保温措施。

D.干冰易升华,气化时膨胀率为600;因此,将干冰存放在完全密封且无排气通道的地方是不合适的。

维护

1机器停止工作时应清理所有管道中的液态二氧化碳;断电后,应清洁机身并用布擦干。

2、检查是否有漏油现象;如果漏油,请拧紧螺钉或更换密封圈。

3、检查是否有掉漆现象;如有掉漆,应刷漆,以防生锈。