Yaliyomo

1. Utangulizi wa jumla

2. Mfumo wa majimaji

3. Mfumo wa kudhibiti umeme

4. Usakinishaji na utume

5. Operesheni

6. Matengenezo

7.Kutatua matatizo

Utangulizi wa jumla

Mashine ya pelletizer ya barafu kavu ni mashine ya barafu kavu ambayo inatengeneza pelleti za barafu kavu kutoka kwa Co2 ya kioevu.

- Vipimo vya jumla ni L1450*W800*H1250mm, uzani wavu ni 580kg

- Uwezo wa uzalishaji

Ukubwa wa barafu kavu: Dia.3mm na 16 mm;

Uzito wa barafu kavu: daraja la chakula ≥1.50

Uwezo wa barafu kavu: 50kg kwa saa

- Kiwango cha ubadilishaji cha Co2 na Ice≥40%

- maudhui ya maji ya Co2 ya kioevu <50ppm;kioevu Co2 shinikizo la kuingiza≤2.0MPa.

Onyo: Ni marufuku kuanzisha mashine ya barafu ikiwa kuna mabadiliko kwenye kujaza au shinikizo la kioevu Co2 tank ya kuhifadhi.

5、Gesi ya Co2 inatoka kupitia bomba moja lenye flange rahisi kwa ajili ya urejelezi ikiwa inahitajika; na kutolewa hewa lazima kuwe wazi.

6, Jumla ya nguvu ni 3.7kw.

Mfumo wa Hidrauliki

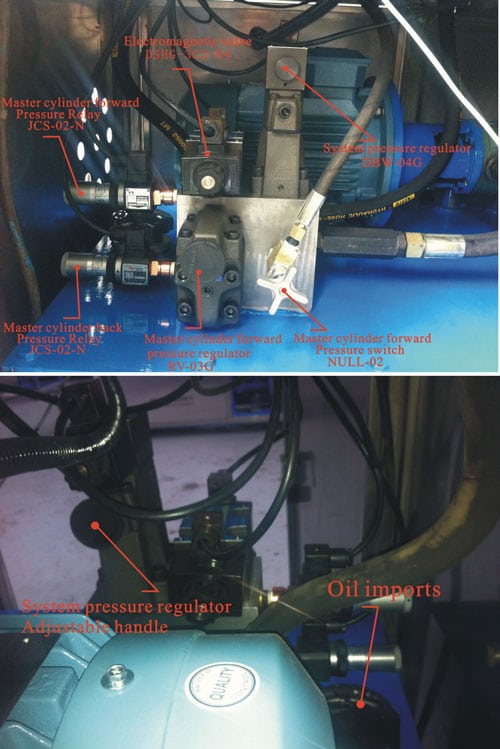

1, Uainishaji wa kiufundi

A. Kiwango cha juu cha shinikizo la mfumo ni 21MPa;

2, Shinikizo la kawaida la kufanya kazi ni chini ya 18MPa;

3, mtiririko wa pampu ni 31L/min;

4, nguvu ya injini: 3.7KW;

5, tanki la mafuta lita 140;

6, ukubwa wa tanki la mafuta ni 80*45*40mm

2、Viwango vya kitaifa 46#, 56#, 68# mafuta mapya ya hidrauliki yasiyo na kuvaa (Mafuta ya hidrauliki yanapaswa kuwa 17-23 CST katika viskoziti ya kinematic na uchafuzi wa mafuta unapaswa kuwa chini ya daraja la 12, kiwango cha NAS.); jaza mafuta kupitia shimo la mafuta hadi kiwango cha juu cha kipimo cha mafuta (karibu jumla ya 350L ya mafuta ya hidrauliki yanahitajika). Safisha kila miezi 6 na kubadilisha mafuta kila miezi 12.

3, Mtihani wa shinikizo la mfumo

Motor imeunganishwa kwa waya kulingana na njia ya kuunganisha waya ya Δna kuhakikisha mwelekeo sahihi wa saa. Anzisha pampu ya mafuta, rekebisha valve ya kufurika ili kudhibiti shinikizo la mfumo. Thamani ya shinikizo la mfumo itaonyeshwa kwenye kipimo cha shinikizo la upande wa kushoto. Na shinikizo la mfumo huu ni 21 MPa. Pendekezo: ni bora kuchagua shinikizo ndogo ikiwa inakidhi mahitaji ya nguvu ya mashine. Kwa njia hii, matumizi ya nguvu yanaweza kupunguzwa; tumerekebisha shinikizo la mfumo huu vizuri kati ya 18-21 Mpa kabla ya mashine kuondoka kiwandani.

4, Mtihani wa relay ya shinikizo

Usambazaji wa shinikizo umejaribiwa na kurekebishwa vizuri kabla ya mashine kuondoka kiwandani. Katika kazi ya kawaida, ikiwa inaanza mapema sana au hakuna mwendo wowote, relay ya shinikizo inaweza kubadilishwa na kifungo mwishoni mwa relay ya shinikizo kwa manually; kuongeza shinikizo kwa mwendo wa saa na kupunguza shinikizo kwa njia ya kinyume cha saa.

5, Ilani:

A, kiwango cha mafuta kwenye upande wa chini, kichujio cha mafuta ya kunyonya kitavuta hewa kwa urahisi na mfumo utatetemeka na suluhisho ni: kujaza mafuta kwenye tanki la mafuta na kuruhusu kiwango cha mafuta juu ya kiashirio cha kioevu na tanki ya mafuta ya idling mara kadhaa kutoa hewa nje ya tangi.

B, Safisha chujio cha mafuta ya kunyonya kila baada ya miezi 6.

C, voltage ya valve solenoid directional na valve solenoid kufurika ni 220V, hivyo kuhakikisha voltage si chini ya 220V.

Mifumo ya Udhibiti wa Umeme

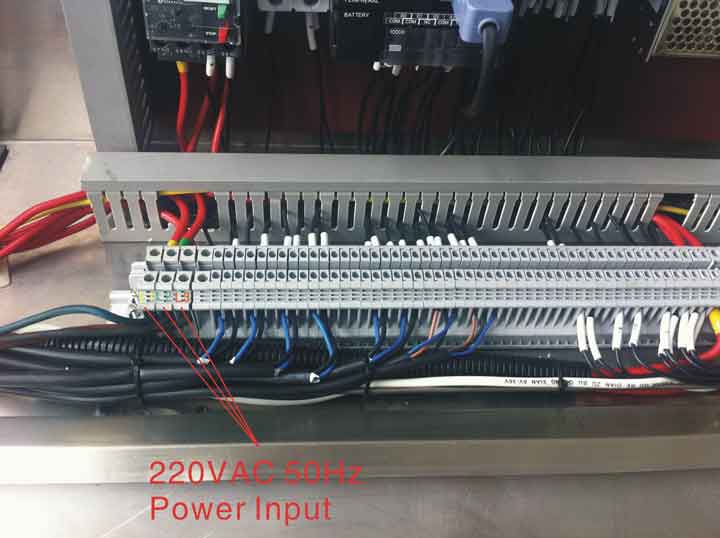

Waya wa kuingiza ni waya wa awamu ya nne na saizi ni 2.52mm; Unganisha waya wa ingizo la umeme na laini ya sifuri ya 220VAC, awamu ya 3 50Hz kwenye kisanduku cha waya cha ingizo upande wa juu kulia wa mashine na uikose kulingana na kanuni za umeme.

Onyo: mashine lazima iwe na msingi salama!

Usanidi na kuanzisha

1 Ufungaji

Ardhi lazima iwe gorofa na laini na tafadhali funga miguu ya mashine. Bomba la utoaji na kipenyo cha valve haipaswi kuwa chini ya φ10, shinikizo ni 1.6 ~ 2.0MPa na bomba la kioevu lazima liwekewe maboksi.

Onyo: duka la kutengeneza barafu kavu linapaswa kuwa na uingizaji hewa mzuri!

2 anzisha mashine ya barafu

(1) fungua sanduku la umeme, sukuma kwenye kivunja mzunguko wa shunt;

(2) washa nguvu kuu kwenye kisanduku cha waya cha kuingiza;

(3) fungua kitufe cha "acha" kwenye ubao;

(4) anza injini ya pampu ya mafuta kwenye skrini ya kugusa;

(5) fanya kazi kwenye skrini ya kugusa kwa hatua zote.

Kumbuka: A. tafadhali angalia ikiwa motor inafanya kazi kwa mwelekeo wa saa wakati wa kuanzisha mara ya kwanza.

B.baada ya kuanzisha pampu ya mafuta, unaweza kubadilisha shinikizo la mfumo wa hidrauliki kwa mikono na kubadilisha shinikizo la hatua; shinikizo la mfumo ni 21MPa wakati mashine inatoka kiwandani.

Onyo: Inakatazwa kabisa kugeuza pampu ya mafuta

(6) kuweka muda wa kulisha na shinikizo la kubakiza wakati kulingana na mahitaji ya usindikaji;

(7) chagua hali ya uendeshaji ya mwongozo au otomatiki;

(8) zima nguvu zote baada ya kazi.

Uendeshaji

Vali 1 ya kwanza fungua mwenyewe ya bomba la kioevu nje na uruhusu kioevu Co2 ingie kwenye mashine.

2, kisha kuanza nguvu, pampu ya mafuta, kuchanganya motor; bonyeza silinda kuu mbele na nyuma, kulisha sekunde 10, kisha bonyeza silinda kuu inayoendelea na nyuma, kulisha sekunde 10, na kurudia kitendo kama hicho mara kadhaa.

Kumbuka: Hatua ya kulisha huanza tu wakati silinda kuu ya mafuta iko mwisho wa nyuma;

Hatua ya automatiska huanza tu wakati silinda kuu ya mafuta inarudi mwisho.

3, Barafu kavu itafanywa kiotomatiki wakati sanduku la mgandamizo limepozwa kabisa.

Tangazo: kila wakati unapoanzisha mashine, kuna gesi nyingi za Co2 zikiwa kwenye mabomba, watumiaji lazima wapulize sanduku la compression na kuondoa kwa Co2 gesi.

4, Kurekebisha barafu kavu

A, rekebisha utoaji wa barafu kavu kwa kurekebisha ongeza kigezo cha muda cha Co2: kigezo cha kurekebisha cha YGBK-50-1 ni 0.4-0.5KG. Ikiwa ni chini ya 0.45kg, itaathiri uzalishaji wa barafu na ikiwa ni zaidi ya kilo 0.5, itasababisha utokaji wa gesi ya Co2 na mbaya kwa mashine.

B, kurekebisha ukubwa wa barafu kavu

Urefu wa barafu kavu inaweza kubadilishwa na kasi ya kurekebisha ya kuchanganya motor.

Ukungu tofauti unaweza kutoa saizi tofauti ya pellets kavu za barafu kutokaΦ3-Φ16.

Onyo:

A Pistoni lazima itolewe chini unapokula kwa mikono.

B wakati wa kulisha valve ya solenoid haiwezi kufungwa, funga mara moja valve ya mpira ya kulisha (iliyotolewa na mtumiaji). C pato la barafu kwa wakati mmoja haliwezi kupita 0.5kg.

C inakatazwa kuweka mikono yako karibu na mlango wa kufunga wa sanduku la compression wakati pampu ya mafuta inafanya kazi.

D Co2 si sumu lakini Co2 yenye wingi mkubwa inaweza kufanya watu wapate kukosa hewa; hivyo ni muhimu kuweka kiwanda cha barafu kavu kuwa na uingizaji hewa mzuri.

E aina thabiti ya Co2-barafu kavu, chini ya 78℃, inaweza kuunguza ngozi kwa urahisi, hivyo hatua za kutengwa zinazofaa ni lazima wakati wa kugusa barafu kavu.

D barafu kavu kwa urahisi inabadilika na kiwango chake cha upanuzi ni 600 wakati inabadilika kuwa gesi; hivyo si sahihi kuhifadhi barafu kavu mahali ambapo hakuna njia ya gesi ya kutoka.

Matengenezo

1Inapaswa kusafisha kioevu cha Co2 katika mabomba yote mashine inapoacha kufanya kazi; baada ya umeme kukatika, inapaswa kusafisha mwili wa mashine na kuifuta kwa kitambaa.

2 Angalia ikiwa mafuta yanavuja; ikiwa mafuta yanavuja, kaza screws au ubadilishe pete ya kuziba.

3Angalia ikiwa rangi imezimwa; ikiwa kuna rangi, piga rangi ikiwa kuna kutu.