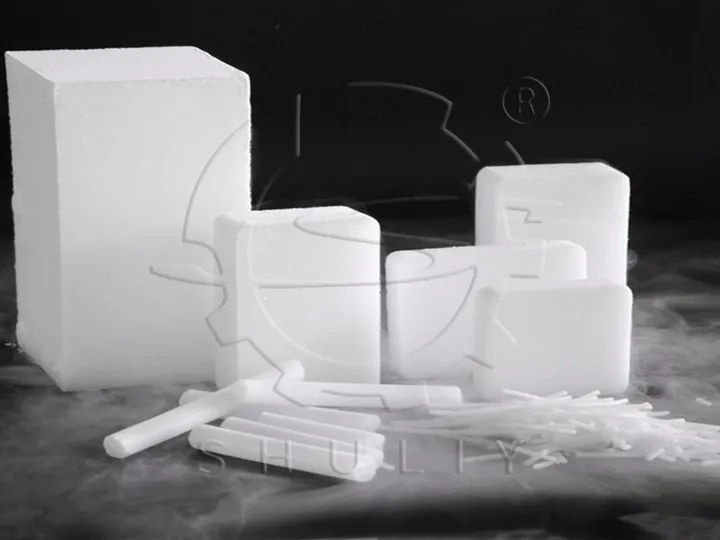

In global cold chain logistics, temperature stability determines product quality, safety, and compliance. For exporters of seafood, meat, frozen food, pharmaceuticals, and biological products, dry ice blocks have become a preferred cooling solution due to their ultra-low temperature (-78.5°C) and residue-free sublimation. Among various options, a custom-sized dry ice block offers significant operational and economic advantages.

The Role of Dry Ice Blocks in Cold Chain Shipping

Unlike traditional ice or gel packs, dry ice does not melt into liquid. It sublimates directly from solid CO₂ to gas, ensuring products remain dry and uncontaminated. This makes dry ice blocks ideal for:

- Long-distance food export

- Air freight of frozen seafood and meat

- Vaccine and pharmaceutical transportation

- Cross-border e-commerce cold chain delivery

Because international shipping durations vary, selecting the correct size and weight of dry ice is critical. Oversized blocks increase cost, while undersized blocks risk temperature fluctuations.

Why Choose Custom Size Dry Ice Block Solutions?

A custom size dry ice block allows exporters to optimize packaging efficiency and cooling performance. Customization is especially important when:

- Carton dimensions are fixed

- Products require precise temperature control

- Shipping time differs by destination

- Air cargo weight limits apply

By matching block size to box dimensions, companies reduce wasted space, improve insulation performance, and control CO₂ consumption more accurately. This results in lower logistics costs and better cold chain reliability.

Investing in Dry Ice Block Production Equipment

For businesses with continuous demand, producing dry ice in-house or factory is more economical than purchasing from suppliers. When evaluating a production setup, companies often consider the dry ice block machine price, production capacity (e.g., 100kg/h–500kg/h), energy consumption, and mold size flexibility.

Modern dry ice block machines support interchangeable molds, enabling manufacturers to produce various block sizes according to customer requirements. This flexibility is especially valuable for exporters serving multiple industries.

Proper Storage: The Key to Minimizing Loss

After production, correct storage is essential. A professional dry ice block storage container with high-density insulation can significantly reduce sublimation loss. These containers maintain low internal temperatures and extend storage time, ensuring maximum efficiency before shipment.

For exporters and cold chain operators, combining custom-sized dry ice blocks with proper storage solutions creates a complete, cost-effective cooling system.